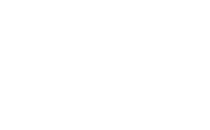

Radio Frequency Curved Ply Forming

R.J. Woodworking produces 3D laminated components and sub-assemblies for manufacturers who need consistency, clean geometry, and scalable production.

Our membrane pressing operation is built around component manufacturing, supporting OEMs with parts designed to integrate directly into larger assemblies and finished products.

Built for Components, Not One-Offs

We approach curved ply forming the same way we approach every service: as a component and sub-assembly manufacturer first.

That means:

-

Tooling designed for repeatability

-

Processes engineered for consistency at volume

-

Components that arrive ready for downstream operations

Whether your curved ply part is structural, cosmetic, or both, our focus is delivering production-ready components—not prototypes that require rework.

Why Radio Frequency Forming

Radio frequency forming allows us to cure laminated plywood assemblies from the inside out, producing stronger bonds, tighter radii, and faster cycle times than conventional press methods.

Key advantages include:

-

Uniform adhesive cure through thick or complex layups

-

Reduced spring-back and improved dimensional stability

-

Faster press cycles for production efficiency

-

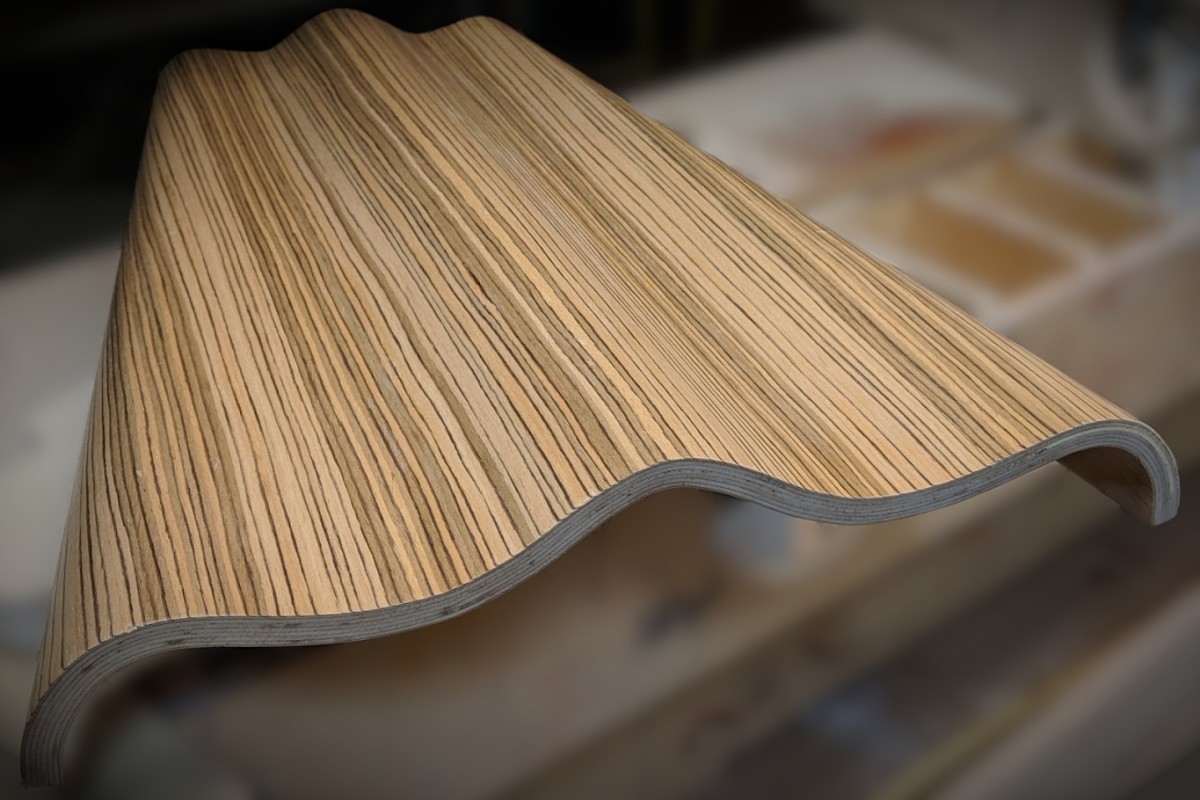

Excellent surface quality for secondary operations

This process is especially well suited for applications where accuracy, strength, and repeatability are non-negotiable.

Capabilities & Applications

Our RF curved ply forming service supports a wide range of geometries, materials, and use cases.

Common applications include:

-

Curved cabinet and furniture components

-

Seating shells and structural forms

-

Architectural panels and radius elements

-

Laminated sub-assemblies ready for finishing or lamination

We routinely collaborate with customers early in the design phase to optimize ply orientation, adhesive selection, and tooling for both performance and manufacturability.

Integrated with Downstream Manufacturing

Curved ply forming is often one step in a larger manufacturing workflow. Because R.J. Woodworking specializes in components and sub-assemblies, we design our RF forming process to integrate cleanly with subsequent operations—such as CNC machining, trimming, or 3D lamination.

The result is fewer handoffs, tighter tolerances, and a more efficient path from raw material to finished part.

A Manufacturing Partner, Not Just a Press

Customers choose R.J. Woodworking for RF curved ply forming because we think like manufacturers, not job shops. We understand production constraints, quality expectations, and the importance of consistency across runs.

If your product depends on curved plywood components that must perform, fit, and scale reliably, we’re built to support that demand.