Comprehensive contract manufacturing

Prototype and manufacturing in one place, American Made, an Fast.

You have a fantastic product, and we are pro’s at making it. Let R.J. Woodworking eliminate the problems in your production flow. With 45 years of experience in contract manufacturing of wood and plastic components, we don’t just make you’r parts. we make them better

A diverse set of manufacturing disciplines allow R.J. Woodworking to be a one stop shop for components, assembly, and finished goods.

Skilled craftsman, and advanced automation guarantee consistency and short lead times.

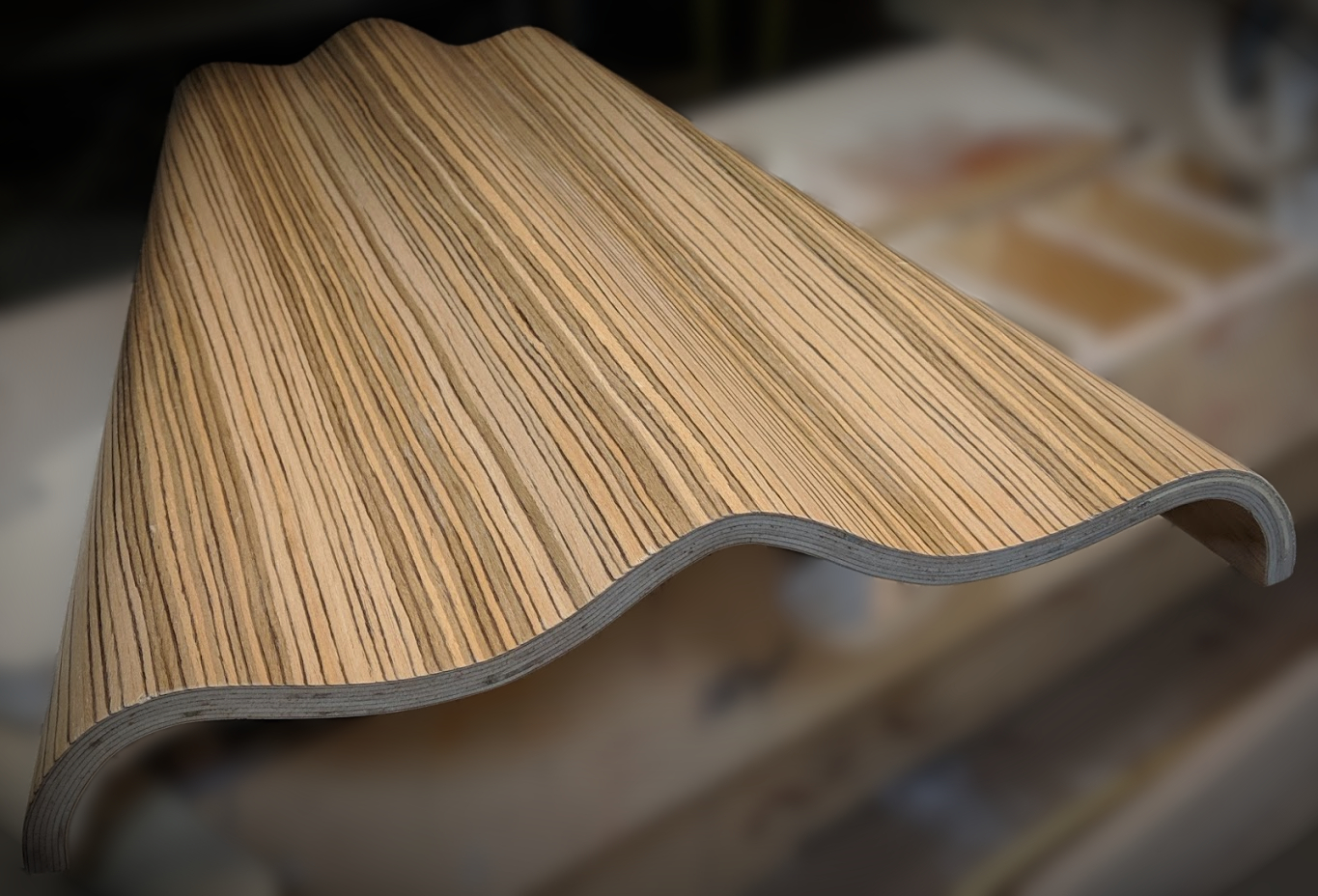

Curved plywood

Structural, finished, and laminated radio frequency curved ply forming.

Casegoods

White label casegoods in laminate, veneer, and 3d thermofoil.

High volume+ CNC routing

Fast, on demand CNC cutting for substrates and structural components

Solid+ surface

Solid surface counterops, retail fixtures and more. All brands of solid surface are available including from Corian to Durasein.

Hybrid manufacturing

RJW and our partners have capabilities in (most) every material, and are always prototyping new materials on the market.

Quality+ standardization

Provide your own quality specifications, or let us build a program for you.

Wood Finishing

Full stain and finish dept. with water and lacquer based finishes. specializing in high volume small components

Primary Manufacturing Services

3D Lamination

Our world isn’t flat. Your components shouldn’t be either. 3d Lamination goes by many names. Thermofoil, thermolaminate, Vinyl wrapped, and 3d laminate are just a few. But whatever you call it, it’s the best way to make a seamless, durable, textured and consistent component or tabletop.

Any core

The core can be nearly any material. MDF is most commonly used. RJW is the industry leader in wrapping complex shapes, and alternative materials such as plastic or metal.

Too many options

3d Laminate comes in so many colors and patterns it can be overwhelming. Woodgrain, brushed metal, aligator skin, PET, PVC…. The choices are endless. Let us be your guide to the perfect covering for your product.

Durable in use, and for your budget

3d laminate is often more durable, and more cost effective than other finishing and sealing options. Better yet, it is also more budget friendly.

Curved Plywood forming

R.J. Woodworking the leader in complex and innovative curved ply manufacturing

Structural

For strength and flexibility, curved plywood has been the way to go since its inception when it was used for WW2 airplane seats. Plywood can give as little or as much as it is designed to without cracking or

Stain, Finish, or 3D Laminated

R.J.W. can apply real wood veneer with our full stain and finishing capabilities, or a wide range of 3D laminate coverings for a component that is more durable and beautiful than you can imagine.

Dimansionally Accurate

Formed plywood isn’t just steamed and bent. It is made from individual layers of hardwood veneer that are pressed into their final form, and radio frequency glued for a dimensionally accurate and stable shape. After forming, the blanks are precision CNC cut and drilled.

Become a Partner

We know what were good at, and for everything else, we have partners. If you are interested in becoming a material or sub-component supplier, apply here and our collaboration team will reach out to schedule a meeting

Prototyping Service that fits your product schedule

Initial product design, process improvement, lead time reduction, and feature evolution are a few of the services our prototype and design team offer. Select the package that works best for your flow below for more information