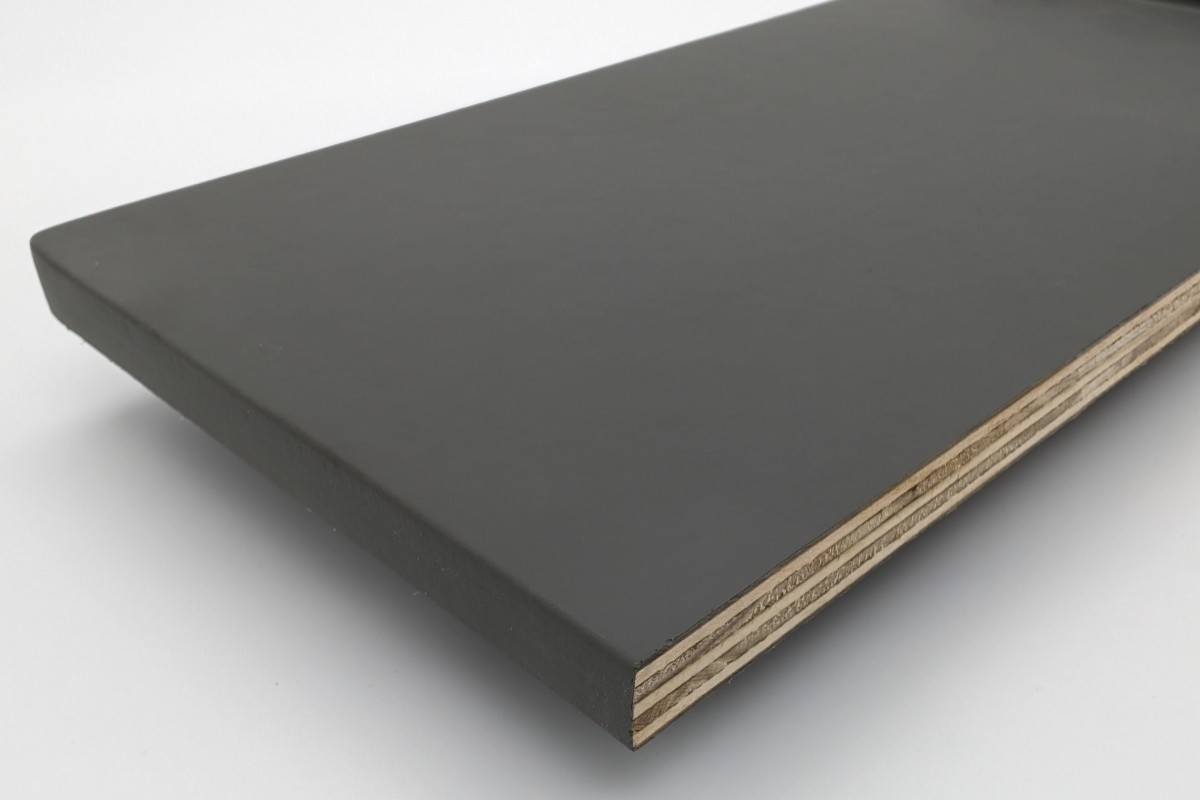

3D Lamination via Membrane Pressing

R.J. Woodworking produces 3D laminated components and sub-assemblies for manufacturers who need consistency, clean geometry, and scalable production.

Our membrane pressing operation is built around component manufacturing, supporting OEMs with parts designed to integrate directly into larger assemblies and finished products.

Built for Manufacturing

We approach 3D lamination as a production process, not a specialty add-on.

Every part is developed to:

-

Maintain dimensional consistency

-

Deliver uniform surface quality

-

Integrate cleanly into downstream assembly

-

Scale reliably from prototype to production

Advanced 3D Pressing Capability

Our membrane pressing process supports:

-

Compound curves and formed profiles

-

Wrapped edges and integrated returns

-

One-piece laminated surfaces

-

Seamless transitions and clean edges

This allows greater design freedom while reducing part count and secondary operations.

Materials Chosen for Performance

We laminate a wide range of decorative and functional films, including:

-

Woodgrain and solid-color finishes

-

Matte, satin, and textured surfaces

-

Films suited for commercial and high-use environments

Materials are selected based on application, durability, and consistency.

Scalable, Repeatable Production

Our processes support:

-

Development and pilot runs

-

Ongoing production programs

-

Program growth without quality drift

We understand how pressing decisions affect manufacturing efficiency—because that’s where our focus has always been.